|

| Biodiesel |

Economic impact

Multiple economic studies have been performed regarding the Economic impact of Biodiesel production. One study, commissioned by the National Biodiesel Board, reported the 2011 production of biodiesel supported 39,027 jobs and more than $2.1 billion in household income. The growth in biodiesel also helps significantly increase GDP (Gross Domestic Product). In 2011, Biodiesel created more than $3 billion in GDP. Judging by the continued growth in the Renewable Fuel Standard and the extension of the biodiesel tax incentive, the number of jobs can increase to 50,725, $2.7 billion in income, and reaching $5 billion in GDP by 2012 and 2013.

One of the main drivers for adoption of biodiesel is energy security. This means that a nation's dependence on oil is reduced, and substituted with use of locally available sources, such as coal, gas, or renewable sources. Thus a country can benefit from adoption of biodiesel, without a reduction in greenhouse gas emissions. While the total energy balance is debated, it is clear that the dependence on oil is reduced.

One example is the energy used to manufacture fertilizers, which could come from a variety of sources other than petroleum. The US National Renewable Energy Laboratory (NREL) states that energy security is the number one driving force behind the US biofuels programme, and a White House "Energy Security for the 21st Century" paper makes it clear that energy security is a major reason for promoting biodiesel. The EU commission president, Jose Manuel Barroso, speaking at a recent EU biofuels conference, stressed that properly managed biodiesel have the potential to reinforce the EU's security of supply through diversification of energy sources.

See this article : Biodiesel Production

|

| Consumption of Biodiesel in the EU |

Environmental Impact

The surge of interest in biodiesels has highlighted a number of environmental effects associated with its use. These potentially include reductions in greenhouse gas emissions, deforestation, pollution and the rate of biodegradation.

According to the EPA's (Environmental Protection Agency) Renewable Fuel Standards Program Regulatory Impact Analysis, released in February 2010, biodiesel from soy oil results, on average, in a 57% reduction in greenhouse gases compared to petroleum diesel, and biodiesel produced from waste grease results in an 86% reduction.

However, environmental organizations, for example, Rainforest Rescue and Greenpeace, criticize the cultivation of plants used for biodiesel production, e.g., oil palms, soybeans and sugar cane. They say the deforestation of rainforests exacerbates climate change and that sensitive ecosystems are destroyed to clear land for oil palm, soybean and sugar cane plantations. Moreover, that biofuels (biodiesel) contribute to world hunger, seeing as arable land is no longer used for growing foods.

The Environmental Protection Agency (EPA) published data in January 2012, showing that biodisel made from palm oil won’t count towards the nation’s renewable fuels mandate as they are not climate-friendly. Environmentalists welcome the conclusion because the growth of oil palm plantations has driven tropical deforestation, for example, in Indonesia and Malaysia.

See this article : Social and Environmental Impact of Palm Oil

Greenhouse gas emissions

An often mentioned incentive for using biodiesel is its capacity to lower greenhouse gas emissions compared to those of fossil fuels. If this is true or not depends on many factors. Especially the effects from land use change have potential to cause even more emissions than what would be caused by using fossil fuels alone.

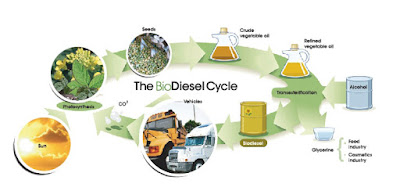

Carbon dioxide (CO2) is one of the major greenhouse gases (sometimes abbreviated GHG, is a gas in an atmosphere that absorbs and emits radiation within the thermal infrared range). Although the burning of biodiesel produces carbon dioxide emissions similar to those from ordinary fossil fuels, the plant feedstock used in the production absorbs carbon dioxide from the atmosphere when it grows.

Plants absorb carbon dioxide through a process known as photosynthesis which allows it to store energy from sunlight in the form of sugars and starches. After the biomass is converted into biodiesel and burned as fuel the energy and carbon is released again. Some of that energy can be used to power an engine while the carbon dioxide is released back into the atmosphere.

When considering the total amount of greenhouse gas emissions it is therefore important to consider the whole production process and what indirect effects such production might cause. The effect on carbon dioxide emissions is highly dependent on production methods and the type of feedstock used. Calculating the carbon intensity of biodiesel is a complex and inexact process, and is highly dependent on the assumptions made in the calculation. A calculation usually includes:

- Emissions from growing the feedstock (e.g. Petrochemicals used in fertilizers)

- Emissions from transporting the feedstock to the factory

- Emissions from processing the feedstock into biodiesel

Other factors can be very significant but are sometimes not considered. These include:

- Emissions from the change in land use of the area where the fuel feedstock is grown.

- Emissions from transportation of the biodiesel from the factory to its point of use.

- The efficiency of the biodiesel compared with standard diesel.

- The amount of Carbon Dioxide produced at the tail pipe. (Biodiesel can produce 4.7% more)

- The benefits due to the production of useful by-products, such as cattle feed or glycerine

If land use change is not considered and assuming today's production methods, biodiesel from rapeseed and sunflower oil produce 45%-65% lower greenhouse gas emissions than petrodiesel. However, there is ongoing research to improve the efficiency of the production process. Biodiesel produced from used cooking oil or other waste fat could reduce CO2 emissions by as much as 85%. As long as the feedstock is grown on existing cropland, land use change has little or no effect on greenhouse gas emissions.

Read this article : Biodiesel

However, there is concern that increased feedstock production directly affects the rate of deforestation. Such clearcutting cause carbon stored in the forest, soil and peat layers to be released. The amount of greenhouse gas emissions from deforestation is so large that the benefits from lower emissions (caused by biodiesel use alone) would be negligible for hundreds of years. Biodiesel produced from feedstock such as palm oil could therefore cause much higher carbon dioxide emissions than some types of fossil fuels.

Pollution

In the United States, biodiesel is the only alternative fuel to have successfully completed the Health Effects Testing requirements (Tier I and Tier II) of the Clean Air Act (1990). Biodiesel can reduce the direct tailpipe-emission of particulates, small particles of solid combustion products, on vehicles with particulate filters by as much as 20 percent compared with low-sulfur (< 50 ppm) diesel.

Particulate emissions as the result of production are reduced by around 50 percent compared with fossil-sourced diesel. Biodiesel has a higher cetane rating than petrodiesel, which can improve performance and clean up emissions compared to crude petro-diesel (with cetane lower than 40). Biodiesel contains fewer aromatic hydrocarbons: benzofluoranthene: 56% reduction; Benzopyrenes: 71% reduction.

Biodegradation

A University of Idaho study compared biodegradation rates of biodiesel, neat vegetable oils, biodiesel and petroleum diesel blends, and neat 2-D diesel fuel. Using low concentrations of the product to be degraded (10 ppm) in nutrient and sewage sludge amended solutions, they demonstrated that biodiesel degraded at the same rate as a dextrose control and 5 times as quickly as petroleum diesel over a period of 28 days, and that biodiesel blends doubled the rate of petroleum diesel degradation through co-metabolism. The same study examined soil degradation using 10 000 ppm of biodiesel and petroleum diesel, and found biodiesel degraded at twice the rate of petroleum diesel in soil.

In all cases, it was determined biodiesel also degraded more completely than petroleum diesel, which produced poorly degradable undetermined intermediates. Toxicity studies for the same project demonstrated no mortalities and few toxic effects on rats and rabbits with up to 5000 mg/kg of biodiesel. Petroleum diesel showed no mortalities at the same concentration either, however toxic effects such as hair loss and urinary discolouring were noted with concentrations of >2000 mg/l in rabbits.

|

| Biodegradable |

Biodegradation in Aquatic Environments

As biodiesel becomes more widely used, it is important to consider how consumption affects water quality and aquatic ecosystems. Research examining the biodegradability of different biodiesel fuels found that all of the biofuels studied (including Neat Rapeseed oil, Neat Soybean oil, and their modified ester products) were “Readily Biodegradable” compounds, and had a relatively high biodegradation rate in water.

Additionally, the presence of biodiesel can increase the rate of diesel biodegradation via co-metabolism. As the ratio of biodiesel is increased in biodiesel/diesel mixtures, the faster the diesel is degraded. Another study using controlled experimental conditions also showed that fatty acid methyl esters, the primary molecules in biodiesel, degraded much faster than petroleum diesel in sea water.

Carbonyl Emissions

When considering the emissions from fossil fuel and biofuel use, research typically focuses on major pollutants such as hydrocarbons. It is generally recognized that using biodiesel in place of diesel results in a substantial reduction in regulated gas emissions, but there has been a lack of information in research literature about the non-regulated compounds which also play a role in air pollution.

One study focused on the emissions of non-criteria carbonyl compounds from the burning of pure diesel and biodiesel blends in heavy-duty diesel engines. The results found that carbonyl emissions of formaldehyde, acetaldehyde, acrolein, acetone, propionaldehyde and butyraldehyde, were higher in biodiesel mixtures than emissions from pure diesel. Biodiesel use results in higher carbonyl emissions but lower total hydrocarbon emissions, which may be better as an alternative fuel source.

Other studies have been done which conflict with these results, but comparisons are difficult to make due to various factors that differ between studies (such as types of fuel and engines used). In a paper which compared 12 research articles on carbonyl emissions from biodiesel fuel use, it found that 8 of the papers reported increased carbonyl compound emissions while 4 showed the opposite. This is evidence that there is still much research required on these compounds.

|

| Biodiesel cycle |

Efficiency and economic arguments

Photosynthesis is known to have an efficiency rate of about 3-6% of total solar radiation and if the entire mass of a crop is utilized for energy production, the overall efficiency of this chain is currently about 1%. While this may compare unfavorably to solar cells combined with an electric drive train, biodiesel is less costly to deploy (solar cells cost approximately US$250 per square meter) and transport (electric vehicles require batteries which currently have a much lower energy density than liquid fuels). A 2005 study found that biodiesel production using soybeans required 27% more fossil energy than the biodiesel produced and 118% more energy using sunflowers.

However, these statistics by themselves are not enough to show whether such a change makes economic sense. Additional factors must be taken into account, such as: the fuel equivalent of the energy required for processing, the yield of fuel from raw oil, the return on cultivating food, the effect biodiesel will have on food prices and the relative cost of biodiesel versus petrodiesel, water pollution from farm run-off, soil depletion[citation needed], and the externalized costs of political and military interference in oil-producing countries intended to control the price of petrodiesel.

The debate over the energy balance of biodiesel is ongoing. Transitioning fully to biofuels could require immense tracts of land if traditional food crops are used (although non food crops can be utilized). The problem would be especially severe for nations with large economies, since energy consumption scales with economic output.

If using only traditional food plants, most such nations do not have sufficient arable land to produce biofuel for the nation's vehicles. Nations with smaller economies (hence less energy consumption) and more arable land may be in better situations, although many regions cannot afford to divert land away from food production.

For third world countries, biodiesel sources that use marginal land could make more sense; e.g., pongam oiltree nuts grown along roads or jatropha grown along rail lines. In tropical regions, such as Malaysia and Indonesia, plants that produce palm oil are being planted at a rapid pace to supply growing biodiesel demand in Europe and other markets. Scientists have shown that the removal of rainforest for palm plantations is not ecologically sound since the expansion of oil palm plantations poses a threat to natural rainforest and biodiversity.

It has been estimated in Germany that palm oil biodiesel has less than one third of the production costs of rapeseed biodiesel. The direct source of the energy content of biodiesel is solar energy captured by plants during photosynthesis. Regarding the positive energy balance of biodiesel:

- When straw was left in the field, biodiesel production was strongly energy positive, yielding 1 GJ biodiesel for every 0.561 GJ of energy input (a yield/cost ratio of 1.78).

- When straw was burned as fuel and oilseed rapemeal was used as a fertilizer, the yield/cost ratio for biodiesel production was even better (3.71). In other words, for every unit of energy input to produce biodiesel, the output was 3.71 units (the difference of 2.71 units would be from solar energy).

Biofuel Production Using Palm Oil

Chemical Composition of Palm Oil

No comments:

Post a Comment