|

| Biodiesel production cycle |

Biodiesel is commonly produced by the transesterification of the vegetable oil or animal fat feedstock. There are several methods for carrying out this transesterification reaction including the common batch process, supercritical processes, ultrasonic methods, and even microwave methods. Chemically, transesterified biodiesel comprises a mix of mono-alkyl esters of long chain fatty acids.

The most common form uses methanol (converted to sodium methoxide) to produce methyl esters (commonly referred to as Fatty Acid Methyl Ester - FAME) as it is the cheapest alcohol available, though ethanol can be used to produce an ethyl ester (commonly referred to as Fatty Acid Ethyl Ester - FAEE) biodiesel and higher alcohols such as isopropanol and butanol have also been used. Using alcohols of higher molecular weights improves the cold flow properties of the resulting ester, at the cost of a less efficient transesterification reaction.

A lipid transesterification production process is used to convert the base oil to the desired esters. Any free fatty acids (FFAs) in the base oil are either converted to soap and removed from the process, or they are esterified (yielding more biodiesel) using an acidic catalyst. After this processing, unlike straight vegetable oil, biodiesel has combustion properties very similar to those of petroleum diesel, and can replace it in most current uses.

The methanol used in most biodiesel production processes is made using fossil fuel inputs. However, there are sources of renewable methanol made using carbon dioxide or biomass as feedstock, making their production processes free of fossil fuels. A by-product of the transesterification process is the production of glycerol (a simple polyol / sugar alcohol compound. It is a colorless, odorless, viscous liquid that is widely used in pharmaceutical formulations).

For every 1 tonne of biodiesel that is manufactured, 100 kg of glycerol are produced. Originally, there was a valuable market for the glycerol, which assisted the economics of the process as a whole. However, with the increase in global biodiesel production, the market price for this crude glycerol (containing 20% water and catalyst residues) has crashed. Research is being conducted globally to use this glycerol as a chemical building block. One initiative in the UK is The Glycerol Challenge.

Usually this crude glycerol has to be purified, typically by performing vacuum distillation. This is rather energy intensive. The refined glycerol (98%+ purity) can then be utilised directly, or converted into other products. The following announcements were made in 2007: A joint venture of Ashland Inc. and Cargill announced plans to make propylene glycol in Europe from glycerol and Dow Chemical announced similar plans for North America. Dow also plans to build a plant in China to make epichlorhydrin from glycerol. Epichlorhydrin is a raw material for epoxy resins.

See this article : Biodiesel

|

| Biodiesel consumption and Production |

Biodiesel Production levels

Global biodiesel production reached 3.8 million tons in 2005. Approximately 85% of biodiesel production came from the European Union. In 2007, in the United States, average retail (at the pump) prices, including federal and state fuel taxes, of B2/B5 were lower than petroleum diesel by about 12 cents, and B20 blends were the same as petrodiesel. However, as part of a dramatic shift in diesel pricing, by July 2009, the US DOE was reporting average costs of B20 15 cents per gallon higher than petroleum diesel ($2.69/gal vs. $2.54/gal). B99 and B100 generally cost more than petrodiesel except where local governments provide a tax incentive or subsidy.

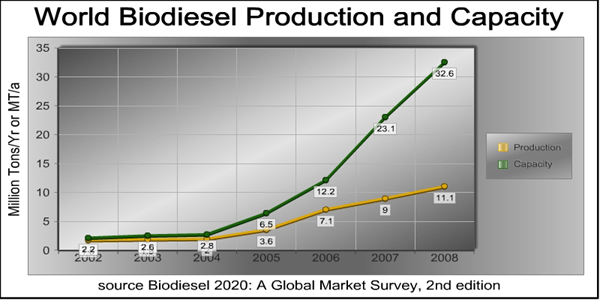

In 2007, biodiesel production capacity was growing rapidly, with an average annual growth rate from 2002-06 of over 40%. For the year 2006, the latest for which actual production figures could be obtained, total world biodiesel production was about 5-6 million tonnes, with 4.9 million tonnes processed in Europe (of which 2.7 million tonnes was from Germany) and most of the rest from the USA. In 2008 production in Europe alone had risen to 7.8 million tonnes.

In July 2009, a duty was added to American imported biodiesel in the European Union in order to balance the competition from European, especially German producers. The capacity for 2008 in Europe totalled 16 million tonnes. This compares with a total demand for diesel in the US and Europe of approximately 490 million tonnes (147 billion gallons). Total world production of vegetable oil for all purposes in 2005/06 was about 110 million tonnes, with about 34 million tonnes each of palm oil and soybean oil.

|

| Annual Biodiesel Production 2011 |

US biodiesel production in 2011 brought the industry to a new milestone. Under the Environmental Protection Agency (EPA) Renewable Fuel Standard, targets have been implemented for the biodiesel production plants in order to monitor and document production levels in comparison to total demand. According to the year-end data released by the EPA, biodiesel production in 2011 reached more than 1 billion gallons. This production number far exceeded the 800 million gallon target set by the EPA. The projected production for 2020 is nearly 12 billion gallons.

See this article : Economic and Environmental Impact of Biodiesel

Biodiesel feedstocks

A variety of oils can be used to produce biodiesel. These include:

- Virgin oil feedstock – rapeseed and soybean oils are most commonly used, soybean oil accounting for about half of U.S. production. It also can be obtained from other crops such as mustard, jojoba, flax, sunflower, palm oil, coconut and hemp.

- Waste vegetable oil (WVO).

- Animal fats including tallow, lard, yellow grease, chicken fat and the by-products of the production of Omega-3 fatty acids from fish oil.

- Algae, which can be grown using waste materials such as sewage and without displacing land currently used for food production.

- Oil from halophytes such as Salicornia bigelovii, which can be grown using saltwater in coastal areas where conventional crops cannot be grown, with yields equal to the yields of soybeans and other oilseeds grown using freshwater irrigation.

- Sewage Sludge - The sewage-to-biofuel field is attracting interest from major companies like Waste Management and startups like InfoSpi, which are betting that renewable sewage biodiesel can become competitive with petroleum diesel on price.

Many advocates suggest that waste vegetable oil is the best source of oil to produce biodiesel, but since the available supply is drastically less than the amount of petroleum-based fuel that is burned for transportation and home heating in the world, this local solution could not scale to the current rate of consumption. Animal fats are a by-product of meat production and cooking. Although it would not be efficient to raise animals (or catch fish) simply for their fat, use of the by-product adds value to the livestock industry (hogs, cattle, poultry).

Today, multi-feedstock biodiesel facilities are producing high quality animal-fat based biodiesel. Currently, a 5-million dollar plant is being built in the USA, with the intent of producing 11.4 million litres (3 million gallons) biodiesel from some of the estimated 1 billion kg (2.2 billion pounds) of chicken fat produced annually at the local Tyson poultry plant. Similarly, some small-scale biodiesel factories use waste fish oil as feedstock.

An EU-funded project (ENERFISH) suggests that at a Vietnamese plant to produce biodiesel from catfish (basa, also known as pangasius), an output of 13 tons/day of biodiesel can be produced from 81 tons of fish waste (in turn resulting from 130 tons of fish). This project utilises the biodiesel to fuel a CHP (Combined Heat and Power, is the use of a heat engine or power station to generate electricity and useful heat at the same time) unit in the fish processing plant, mainly to power the fish freezing plant.

|

| World Biodiesel Production and Capacity |

Advantages of Biodiesel

The color of biodiesel ranges from golden and dark brown, depending on the production method. It is slightly miscible with water, has a high boiling point and low vapor pressure. *The flash point of biodiesel (>130 °C, >266 °F) is significantly higher than that of petroleum diesel (64 °C, 147 °F) or gasoline (−45 °C, -52 °F). Biodiesel has a density of ~ 0.88 g/cm³, higher than petrodiesel ( ~ 0.85 g/cm³). Biodiesel contains virtually no sulfur, and it is often used as an additive to Ultra-Low Sulfur Diesel (ULSD) fuel to aid with lubrication, as the sulfur compounds in petrodiesel provide much of the lubricity.

Biodiesel has promising lubricating properties and Cetane ratings (Cetane number or CN is an indicator of the combustion speed of diesel fuel. It is an inverse of the similar octane rating for gasoline / petrol. The CN is an important factor in determining the quality of diesel fuel) compared to low sulfur diesel fuels. Depending on the engine, this might include high pressure injection pumps, pump injectors (also called unit injectors) and fuel injectors.

The calorific value of biodiesel is about 37.27 MJ/kg. This is 9% lower than regular Number 2 petrodiesel. Variations in biodiesel energy density is more dependent on the feedstock used than the production process. Still, these variations are less than for petrodiesel. It has been claimed biodiesel gives better lubricity and more complete combustion thus increasing the engine energy output and partially compensating for the higher energy density of petrodiesel.

Biodiesel Lubricity

Lubricity of fuel plays an important role in wear that occurs in an engine. An engine relies on its fuel to provide lubricity for the metal components that are constantly in contact with each other. Biodiesel is a much better lubricant compared with petroleum diesel due to the presence of esters. Tests have shown that the addition of a small amount of biodiesel to diesel can significantly increase the lubricity of the fuel in short term.

Fuel efficiency

The power output of biodiesel depends on its blend, quality, and load conditions under which the fuel is burnt. The thermal efficiency for example of B100 as compared to B20 will vary due to the BTU content of the various blends. Thermal efficiency of a fuel is based in part on fuel characteristics such as: viscosity, specific density, and flash point; these characteristics will change as the blends as well as the quality of biodiesel varies. The American Society for Testing and Materials has set standards in order to judge the quality of a given fuel sample.

Regarding brake thermal efficiency one study found that B40 was superior to traditional counterpart at higher compression ratios (this higher brake thermal efficiency was recorded at compression ratios of 21:1). It was noted that, as the compression ratios increased, the efficiency of all fuel types - as well as blends being tested - increased; though it was found that a blend of B40 was the most economical at a compression ratio of 21:1 over all other blends. The study implied that this increase in efficiency was due to fuel density, viscosity, and heating values of the fuels.

|

| Advantages of Biodiesel |

Combustion

Fuel systems on the modern diesel engine were not designed to accommodate biodiesel, while many heavy duty engines are able to run with biodiesel blends e.g. B20. Traditional direct injection fuel systems operate at roughly 3,000 psi at the injector tip while the modern common rail fuel system operates upwards of 30,000 PSI at the injector tip. Components are designed to operate at a great temperature range, from below freezing to over 1,000 degrees Fahrenheit.

Biodiesel fuel is expected to burn efficiently and produce as few emissions as possible. As emission standards are being introduced to diesel engines the need to control harmful emissions is being designed into the parameters of diesel engine fuel systems. The traditional inline injection system is more forgiving to poorer quality fuels as opposed to the common rail fuel system. The higher pressures and tighter tolerances of the common rail system allows for greater control over atomization and injection timing.

This control of atomization as well as combustion allows for greater efficiency of modern diesel engines as well as greater control over emissions. Components within a diesel fuel system interact with the fuel in a way to ensure efficient operation of the fuel system and so the engine. If an out-of-specification fuel is introduced to a system that has specific parameters of operation, then the integrity of the overall fuel system may be compromised. Some of these parameters such as spray pattern and atomization are directly related to injection timing.

One study found that during atomization biodiesel and its blends produced droplets that were greater in diameter than the droplets produced by traditional petrodiesel. The smaller droplets were attributed to the lower viscosity and surface tension of traditional petrol. It was found that droplets at the periphery of the spray pattern were larger in diameter than the droplets at the center this was attributed to the faster pressure drop at the edge of the spray pattern; there was a proportional relationship between the droplet size and the distance from the injector tip. It was found that B100 had the greatest spray penetration, this was attributed to the greater density of B100.

Having a greater droplet size can lead to; inefficiencies in the combustion, increased emissions, and decreased horse power. In another study it was found that there is a short injection delay when injecting biodiesel. This injection delay was attributed to the greater viscosity of Biodiesel. It was noted that the higher viscosity and the greater cetane rating of biodiesel over traditional petrodiesel lead to poor atomization, as well as mixture penetration with air during the ignition delay period.

Another study noted that this ignition delay may aid in a decrease of NOx (a generic term for the mono-nitrogen oxides NO and NO2 / nitric oxide and nitrogen dioxide. They are produced from the reaction of nitrogen and oxygen gases in the air during combustion, especially at high temperatures. In areas of high motor vehicle traffic, such as in large cities, the amount of nitrogen oxides emitted into the atmosphere as air pollution can be significant) emission.

Biodiesel Emissions Effect

Emissions are inherent to the combustion of diesel fuels that are regulated by the U.S. Environmental Protection Agency (EPA). As these emissions are a byproduct of the combustion process in order to ensure E.P.A. compliance a fuel system must be capable of controlling the combustion of fuels as well as the mitigation of emissions. There are a number of new technologies that are becoming phased in to control the production of diesel emissions. The Exhaust Gas Recirculation system (EGR) and the Diesel Particulate Filter (DPF), are both designed to mitigate the production of harmful emissions.

While studying the effect of biodiesel on a D.P.F. it was found that though the presence of sodium and potassium carbonates aided in the catalytic conversion of ash, as the diesel particulates are catalyzed, they may congregate inside the D.P.F. and so interfere with the clearances of the filter. This may cause the filter to clog and interfere with the regeneration process. In a study on the impact of E.G.R. rates with blends of jathropa biodiesel it was shown that there was a decrease in fuel efficiency and torque output due to the use of biodiesel on a diesel engine designed with an E.G.R. system.

It was found that CO and CO2 emissions increased with an increase in exhaust gas recirculation but NOx levels decreased. The opacity level of the Jathropa blends was in an acceptable range, where traditional diesel was out of acceptable standards. It was shown that a decrease in Nox emissions could be obtained with an E.G.R. system. This study showed an advantage over traditional diesel within a certain operating range of the E.G.R. system. Currently blended biodiesel fuels (B5 and B20) are being used in many heavy-duty vehicles especially transit buses in US cities. Characterization of exhaust emissions showed significant emission reductions compared to regular diesel.

You may like this articles :

Social and Environmental Impact of Palm Oil

Palm Oil Production and The Nutrition for Health

No comments:

Post a Comment